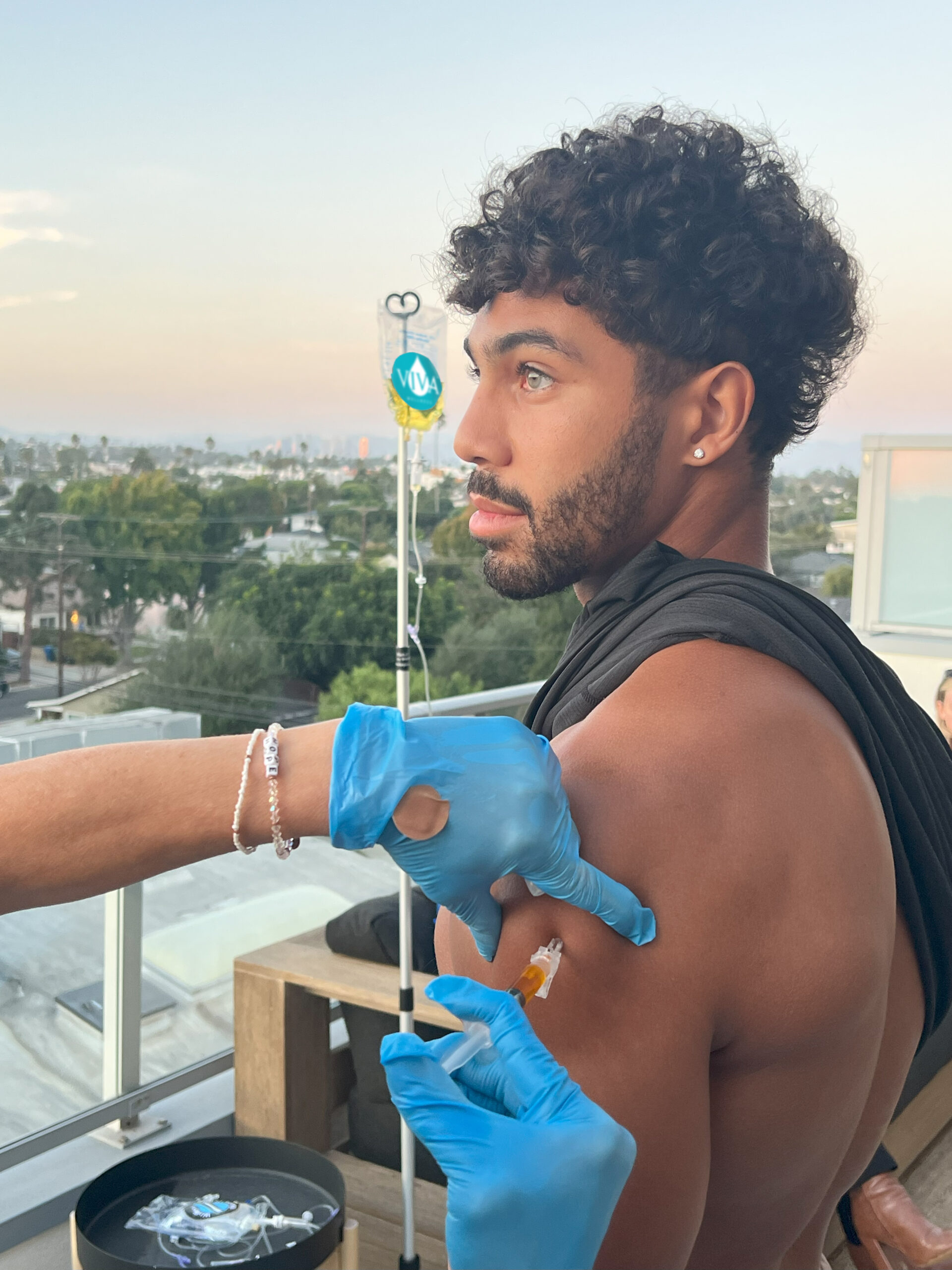

Are you worried about the safety of IV Drips you get at home? IV infusion treatments contain a special mix of vitamins and nutrients that go straight into your bloodstream. This blog will explain how we use strict quality assurance in healthcare to check every part of our process, from sterile compounding to choosing medical-grade ingredients.

Key Takeaways

- Each IV drip contains medical-grade vitamins and nutrients, such as vitamin C, B-complex, magnesium, and zinc.

- Trained professionals mix ingredients in sterile environments to prevent contamination and meet strict pharmaceutical standards.

- All IV drip components must pass purity, potency, and sterility tests before use; this process checks for harmful contaminants and ensures accurate dosing.

- Facilities inspect packaging integrity and keep detailed records for safety, transparency, and easy recall if needed.

- The entire quality control process—from ingredient sourcing to final product testing—focuses on patient safety and effectiveness of the IV therapy.

Sourcing High-Quality Ingredients

We choose vitamins and nutrients that meet medical-grade standards. Our team works with trusted suppliers to ensure ingredient quality.

Selection of medical-grade vitamins and nutrients

Clinics use medical-grade vitamins and nutrients to create IV drip blends for specific health goals. A complete guide helps staff select the most effective and safe ingredients for each infusion.

These vitamins and minerals must meet strict pharmaceutical standards before entering the IV therapy process. Clinics commonly use ingredients like vitamin C, B-complex, magnesium, and zinc in their IV solutions.

Medical staff also follow IV preparation guidelines and check component sources to match patient needs.

Vendors supply nutrients and vitamins that pass purity and potency tests. Facilities check packaging integrity to ensure quality from the start. Providers also rely on pharmaceutical standards to guarantee IV drip safety for every treatment.

The preparation stage includes ingredient measurement and mixing by trained professionals. Final ingredient selections support several therapies, including those for dehydration, beauty, and wellness, such as the popular Myers’ Cocktail.

Rigorous Quality Control Process

We follow strict quality control standards to ensure each IV drip ingredient meets pharmaceutical guidelines. Our team conducts thorough testing at every stage of production. This process guarantees the safety and effectiveness of our products.

Curious about how we achieve this?

Sterile compounding and pharmaceutical standards

The quality of our IV drip ingredients depends on strict sterile compounding practices. These practices ensure safety and effectiveness.

- Medical-grade vitamins and nutrients undergo thorough selection processes to guarantee their quality.

- Sterile compounding involves creating mixtures in clean environments, minimizing contamination risks.

- Trained professionals follow established pharmaceutical standards during the mixing process.

- Each ingredient is measured accurately to maintain the potency of the final product.

- The facility conducts regular inspections to uphold cleanliness and organization throughout the production area.

- Equipment used for compounding must meet safety regulations set by health authorities.

- Post-production testing verifies that solutions remain free from harmful contaminants and pathogens.

- Quality control procedures are critical for ensuring IV products provide reliable diagnostic results during patient care.

- Inspection of IV set packaging integrity starts before any ingredient enters the compounding process.

- Compliance with pharmaceutical guidelines helps maintain high standards in every stage of preparation.

Ensuring Safety and Efficacy

We conduct thorough tests to check each ingredient for purity and potency. Our process confirms that every element meets strict standards for safety and sterility.

Testing for purity, potency, and sterility

Testing for purity, potency, and sterility is essential in ensuring the safety of IV drip ingredients. Quality control procedures guarantee that these solutions meet pharmaceutical standards.

- Purity testing examines each ingredient to confirm it is free from contaminants and pathogens. This step protects patients from harmful substances that could cause danger during treatment.

- Potency evaluation measures the strength of each vitamin and nutrient present in the IV solution. Accurate dosing ensures that patients receive effective treatments tailored to their health goals.

- Sterility tests verify that IV solutions remain free from bacteria or viruses throughout production. Maintaining sterility prevents infections and supports safe administration into the bloodstream.

- Post-production testing occurs after compounding to confirm that all measurements are precise and accurate. This process reassures both clinics and patients about the reliability of their IV therapies.

- Inspection of packaging integrity plays a critical role in quality assurance checks before distribution. A secure package reduces risks of contamination during transport and storage.

- Flavoring agents undergo testing for safety, ensuring they do not interfere with the effectiveness of the infusion itself. This step guarantees a pleasant experience for patients receiving treatment.

- Comprehensive records document every test conducted on ingredients, strengthening traceability during audits or recalls if necessary. Proper record-keeping upholds transparency in manufacturing practices.

Quality control forms the foundation of safe and effective IV therapy treatments delivered from the lab to your living room.

Conclusion

We ensure our IV drip ingredients meet the highest standards. Our quality control process checks for purity and sterility every step of the way. Each ingredient passes rigorous testing before reaching your living room.

You can feel confident knowing that safety and efficacy drive our approach. Great health starts with what goes into your body, so trust the quality of our IV solutions!

FAQs

1. What steps do you take to ensure the quality of your IV drip ingredients?

We source each ingredient from trusted suppliers. Our team tests every batch in a controlled laboratory setting. We check for purity and safety before packaging.

2. How do you maintain ingredient safety during transport to my home?

We use secure, temperature-controlled containers that protect the integrity of each solution. Our logistics partners track shipments closely to prevent any contamination or spoilage.

3. Who checks your IV drip ingredients for quality?

Our trained scientists inspect all materials at multiple stages in our lab process. They follow strict guidelines set by health authorities and document their findings with detailed records.

4. Why is laboratory testing important for IV drip solutions used at home?

Lab testing confirms that each formula meets required standards for strength, cleanliness, and stability; this protects your health when using our products in your living room environment.